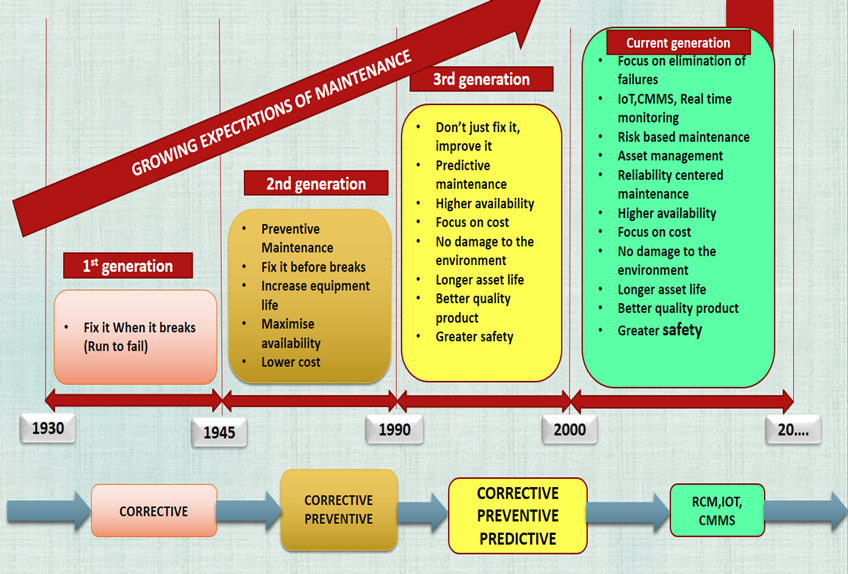

Generations of Maintenance

Over a timeline, the expectation of maintenance increases significantly. People understand proper machine maintenance can contribute to production, industry growth & profit.

Initially, maintenance is limited to fixing the problems, Nowadays it’s a part of the business & more proactive.

Let’s go back in time and take a look at maintenance’s history

If we count on history, we can categorize maintenance in 4 generations. Shown in Fig.

Based on Reliability Centred Maintenance, generations were characterized by changes in three areas:

· Expectations of Maintenance

· Views on Equipment Failure

· Maintenance Techniques

- The First Generation of Maintenance

This is the first generation of maintenance, before land up to the Second World War, could be described in the following terms:

Expectations of Maintenance:

- Fix equipment when it breaks

Views on Equipment Failure:

- All equipment “Wears out”

Maintenance Techniques:

- Fundamental Repair Skills

2. The Second Generation of Maintenance:

After the Second world war, up to the 1990s could be described in the following

Expectations of Maintenance:

- Higher equipment availability

- Longer equipment life

- Lower Maintenance Costs

Views on Equipment Failure:

- Equipment complies with the “Bath-Tub” Curve

Expectations of Maintenance:

- Higher equipment availability & reliability

- Greater safety

- No environmental damage

- Better Product Quality

- Longer Equipment Life

- Greater Cost Effectiveness

Views on Equipment Failure:

- There are 6 failures patterns, following the research of Nowlan and Heap

Maintenance Techniques:

- Condition Monitoring

- Design for Maintainability and Reliability

- Reliability-centered maintenance

- Computer aided maintenance management and information system

- Proactive and strategic thinking

- Failure Modes and Effects Analysis (FMEA)